JEPLAN, INC. (Representative Director, President, and Chief Executive Officer: Masaki Takao; hereinafter “JEPLAN”) is announcing the start of its verification study (hereinafter “the study”) beginning September 2023, which recycles textile products like blended fabrics and other materials (hereinafter “blended fabrics”) through pyrolytic gasification in order to achieve further circulation of used textiles.

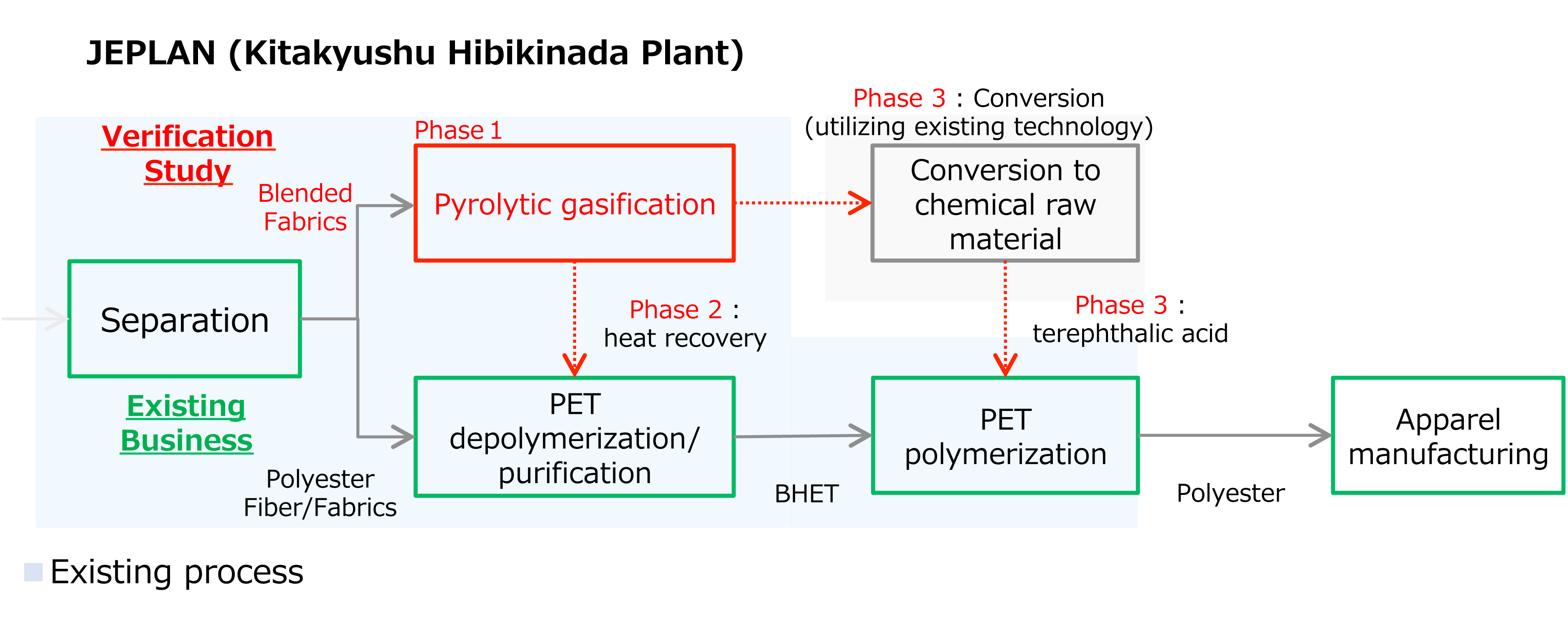

JEPLAN collaborates with Hitachi Zosen Corporation (President & Chief Executive Officer: Sadao Mino) to conduct the study of pyrolytic gasification of blended fabrics at the Kitakyushu Hibikinada Plant (1-120-6 Hibikimachi, Wakamatsu-ku, Kitakyushu, Fukuoka; hereinafter “the plant”). Although the study must be conducted in phases in order to achieve circulation, JEPLAN’s ultimate goal is to derive gases from used textiles and utilize them as raw material for recycled polyester. This study has been selected as a subject theme of the “Environmental Future Technology Development Subsidy Program of Kitakyushu City” in 2023.

The recycling rate for textile-to-textile recycling across the globe amounts to less than 1%*. This figure includes pre-consumer waste, implying that the textile-to-textile recycling rate for post-consumer waste (used clothing worn by consumers) is even lower. While recycling is technically possible with mono materials like polyester, today’s apparel industry is composed of products made of blended fabrics with various ratios of materials, posing many problems in its recycling.

Under its Vision to “BRING everyone into circular economy,” JEPLAN promotes the circulation of resources while building relations throughout a wide supply chain. In the field of textiles, JEPLAN began collaborating with partners in the apparel industry to collect used clothing from their stores starting 2010. Utilizing proprietary technologies, polyester is processed at the plant through a method called “chemical recycling” to perform purification processing, to which they are later manufactured and sold as recycled polyester resin. In addition to business-to-business sales of this Sustainable recycled polyester resin made from 100% fiber origin, JEPLAN also provides direct-to-consumer products through its in-house apparel brand, BRING™. In 2021, it opened own apparel store BRING EBISU, furthering its efforts to promote circular economy within society.

The study is to be conducted in phases to achieve recycling of blended fabrics. The first phase is evaluation of the pyrolytic gasification of blended fabrics with bench-scale equipment. Next is the evaluation of heat recovery with derived gases at the plant. The third phase is the conversion of derived gases to chemical raw materials, and its generation into terephthalic acid to use as upcycled polyester material within the plant. Through these phases, JEPLAN aims to upcycle textile products and deliver them to consumers once again.

JEPLAN Group will continue working towards its Vision to “BRING everyone into circular economy,” collaborating with partners within and outside Japan to unite as a Group and lead the way towards a circular economy.

*¹ First Deliberation Meeting for the Resource Circulation System of Textile Products; See Page 5 of “Technology Development for the Establishment of Resource Circulation System of Textile Products”

https://www.meti.go.jp/shingikai/mono_info_service/resource_recycling/pdf/001_05_00.pdf

■ Environmental Future Technology Development Subsidy Program of Kitakyushu City

(https://www.city.kitakyushu.lg.jp/kankyou/file_0474.html)

A program funded by the environmental future tax of Kitakyushu City with the goal to lead the way in solving environmental issues and advance the environmental industry for the realization of a circular and decarbonized society

■ Kitakyushu Hibikinada Plant

Location: 1- 120-6 Hibikimachi, Wakamatsu-ku, Kitakyushu, Fukuoka

Established: Completed in 2017