What is Life Cycle Assessment (LCA)?

LCA is a numerical value that quantitatively expresses the environmental impact of a product throughout its life cycle (sourcing → raw material production → product production → consumption → disposal/recycling) or at specific stages thereof.

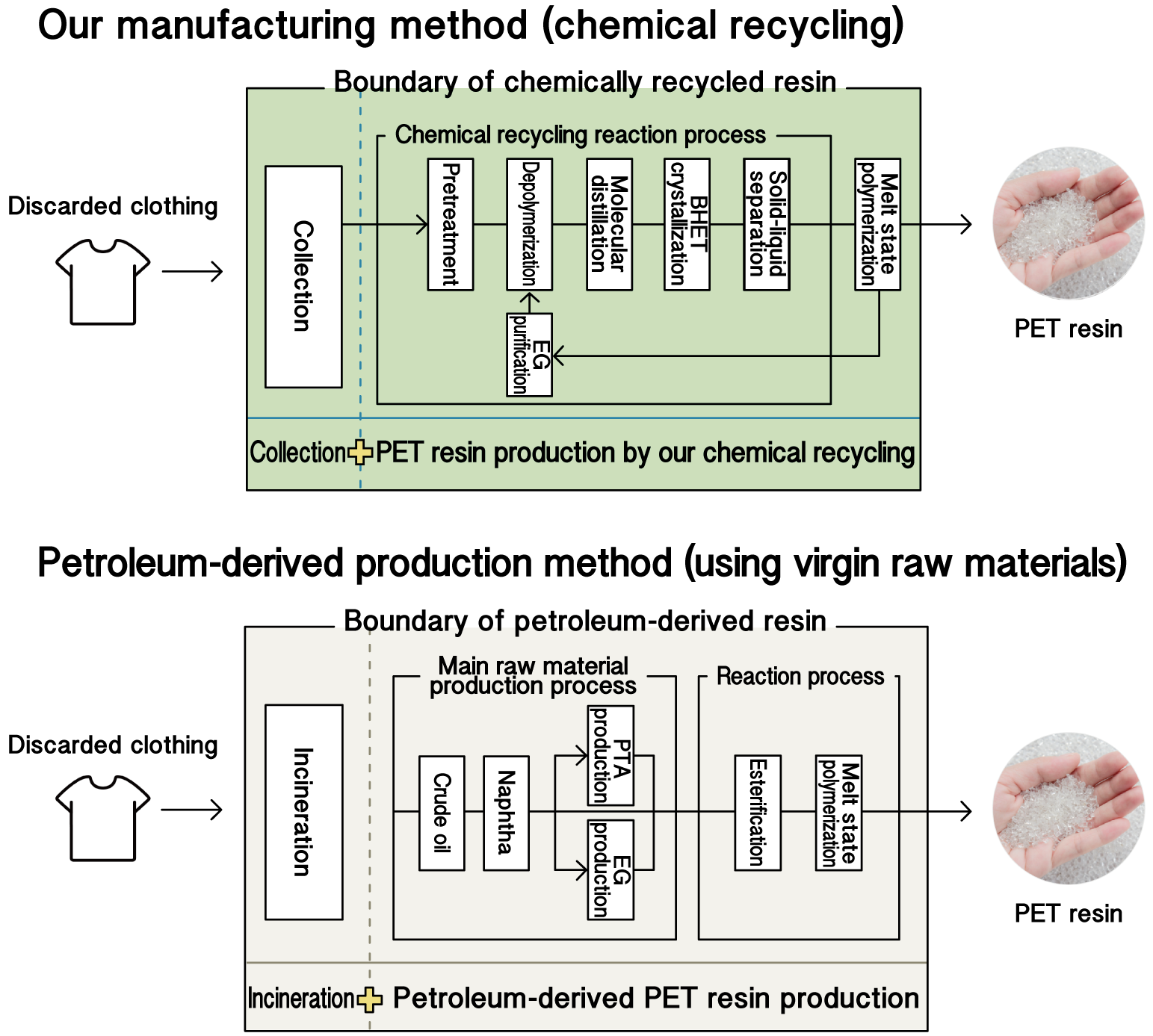

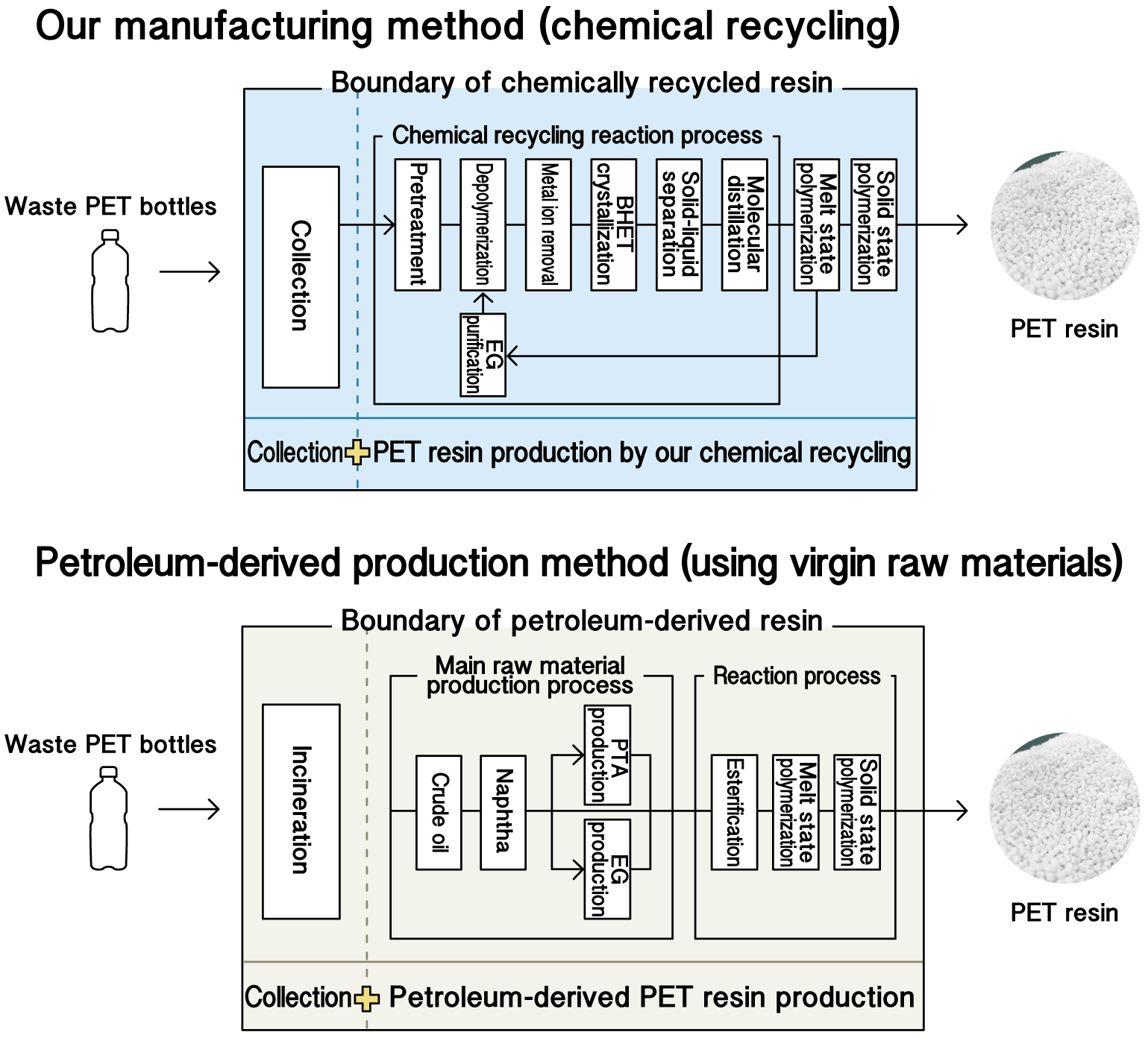

In our LCA calculations for our production of PET resin, we compare the total CO2 emissions for each process, from the collection of waste clothing or PET bottles to the production of recycled PET resin and from the incineration of waste clothing or waste PET bottles to the production of virgin PET resin.

LCA for PET resin production

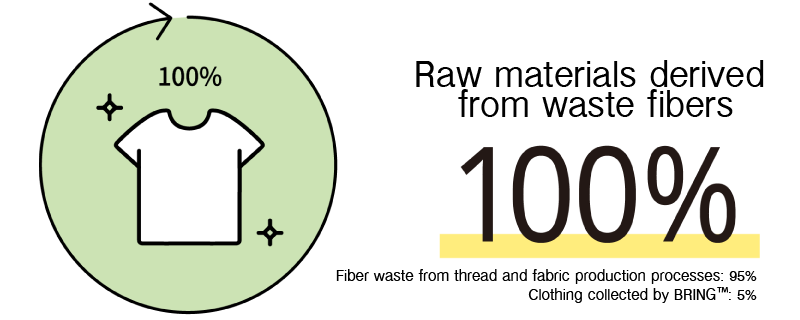

Clothing recycling

Our chemical recycling process uses 100% raw materials derived from waste fibers (Fiber waste from thread and fabric production processes: 95%, clothing collected by BRING: 5%)

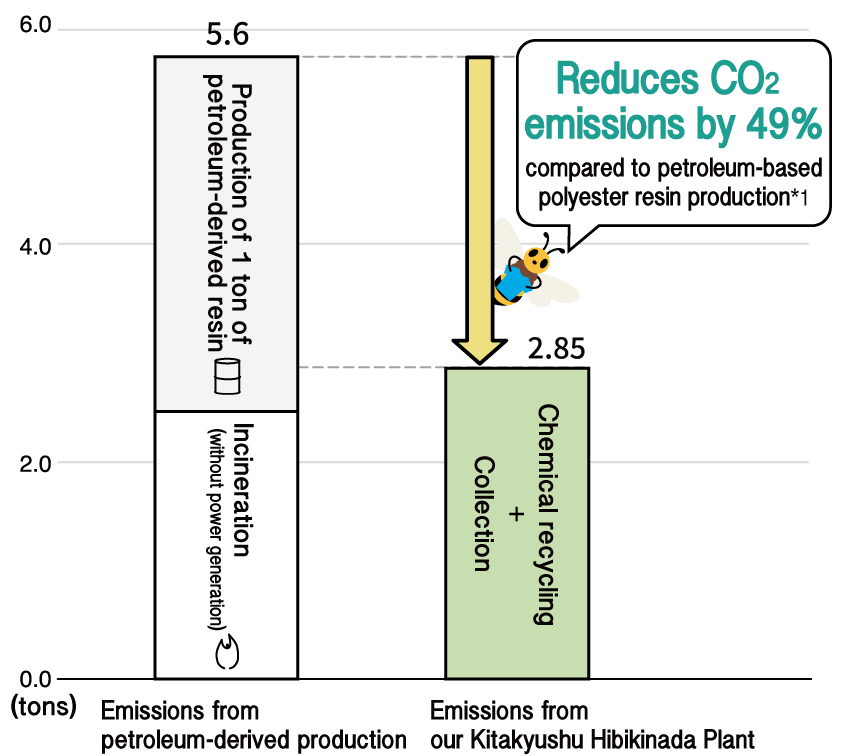

Comparison of CO2 emissions when producing

1 ton of polyester (PET) resin

CO2 emissions from the production of PET resin at our Kitakyushu Hibikinada Plant are approximately 49% lower than production from petroleum-derived raw materials.

The boundaries for LCA calculation are shown in the figure above.

Conventional: [incineration of clothing] + [petroleum-derived PET resin production] vs.

Our company: [Collection of clothing] + [PET resin production by chemical recycling] are compared.

Although our manufacturing process allows for multiple cycles of collection and recycling, the boundary settings for this LCA calculation assume a single cycle.

*1 The Ministry of the Environment commissioned Deloitte Tohmatsu Consulting to conduct an LCA study (*2) on our technology in fiscal year 2019. The results show a 28% reduction in carbon dioxide emissions compared to petroleum-derived PET resins.

*2 Deloitte Tohmatsu Consulting LLC, “FY2019 Deliverable: Carbon dioxide reduction benefits of chemical recycling and its evaluation and verification as a system for a decarbonized society.” Work commissioned by the Ministry of the Environment in FY2019. 2020,3.153p

FY2019 Deliverable: Carbon dioxide reduction benefits of chemical recycling and its evaluation and verification as a system for a decarbonized society | Bibliographic details | National Diet Library Online (ndl.go.jp)

Based on this figure and composition of the power supply of Kyushu Electric Power Company (*3), which is used at our plant, we arrived at the 49% CO2 reduction effect.

* 3 Kyushu Electric Power Company’s power supply composition, non-fossil certificate usage, and CO2 emission coefficient [retail supply] (kyuden.co.jp)

PET: Polyethylene terephthalate, BHET: Bis(2-Hydroxyethyl)terephthalate, EG: Ethylene Glycol

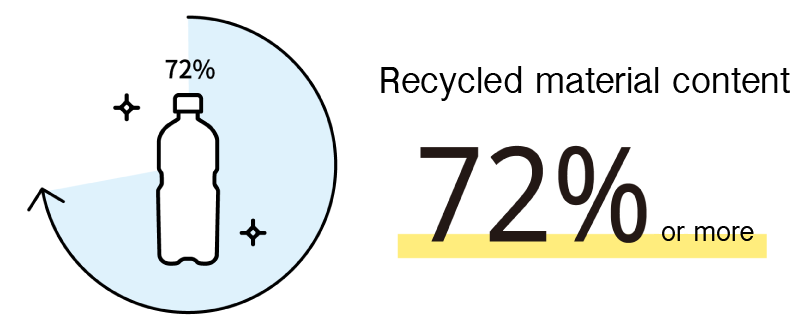

PET bottle recycling environmental claim

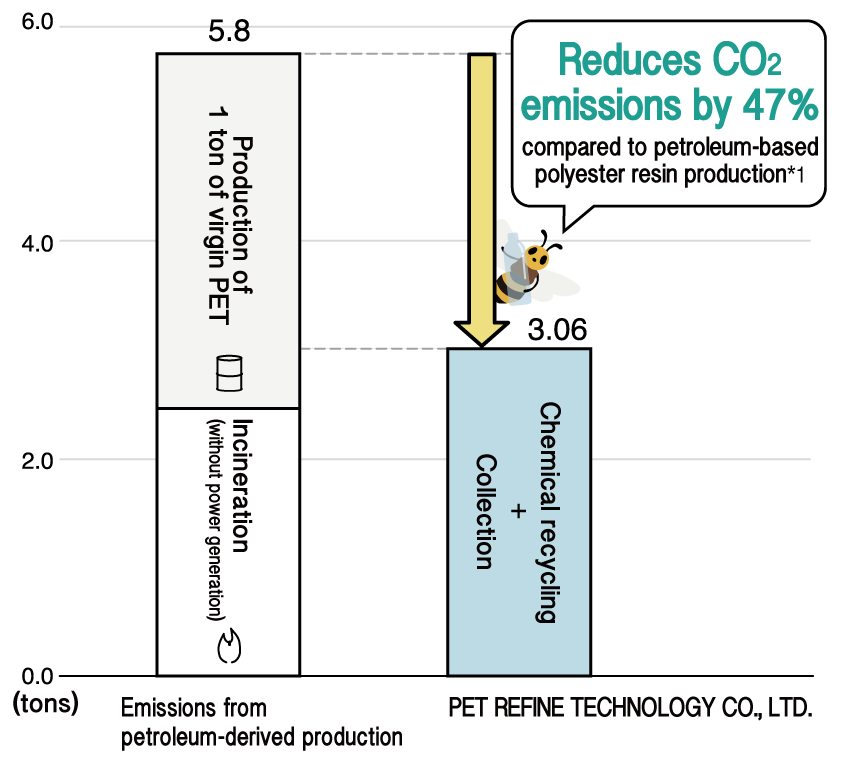

Comparison of CO2 emissions when producing

1 ton of polyester (PET) resin

CO2 emissions from the production of PET resin at PET Refine Technology Co., Ltd. are approximately 47% lower than production from petroleum-derived raw materials.

The boundaries for LCA calculation are shown in the figure above.

Conventional: [incineration of waste PET bottles] + [petroleum-derived PET resin production] vs.

Our company: [Collection of waste PET bottles] + [PET resin production by chemical recycling] are compared.

Although our manufacturing process allows for multiple cycles of collection and recycling, the boundary settings for this LCA calculation assume a single cycle.

*1 The Ministry of the Environment commissioned Deloitte Tohmatsu Consulting to conduct an LCA study (*2) on our technology in fiscal year 2019. The results show a 45% reduction in carbon dioxide emissions compared to petroleum-derived PET resins.

*2 Deloitte Tohmatsu Consulting LLC, “FY2019 Deliverable: Carbon dioxide reduction benefits of chemical recycling and its evaluation and verification as a system for a decarbonized society.” Work commissioned by the Ministry of the Environment in FY2019. 2020,3.153p

FY2019 Deliverable: Carbon dioxide reduction benefits of chemical recycling and its evaluation and verification as a system for a decarbonized society | Bibliographic details | National Diet Library Online (ndl.go.jp)

Based on this figure and composition of the power supply of Tokyo Electric Power Company (*3), which is used at our plant, we arrived at the 47% CO2 reduction effect.

*3 https://www.tepco.co.jp/ep/power_supply/2019.html

PET: Polyethylene terephthalate, BHET: Bis(2-hydroxyethyl)terephthalate, EG: Ethylene glycol, TPA: Terephthalic acid, IPA: Isophthalic acid