JEPLAN, INC. (Representative Director, President, and Chief Executive Officer: Masaki Takao, hereinafter referred to as “JEPLAN”) has decided to enter into a business partnership with TANAKA PRECIOUS METAL GROUP Co., Ltd. (CEO: Koichiro Tanaka) to reduce CO₂ emissions and promote the recycling organic materials in the precious metal recovery processes of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd., a company engaged in precious metals business.

This initiative represents a collaboration between TANAKA, committed to advancing a circular economy in the precious metals field, and JEPLAN, which has been pursuing similar goals in the plastics field, with both companies aiming to achieve a decarbonized, circular society.

■ Initiatives by Both Companies Thus Far for Realizing a Circular Society

JEPLAN has established its own proprietary chemical recycling technology specifically for polyethylene terephthalate (PET), a type of plastic. By utilizing this technology to promote resource circulation of PET bottles and polyester textiles, JEPLAN not only reduces the need for new petroleum resources but also enables the recycling of limited resources, contributing to advancing efforts toward realizing a circular economy.

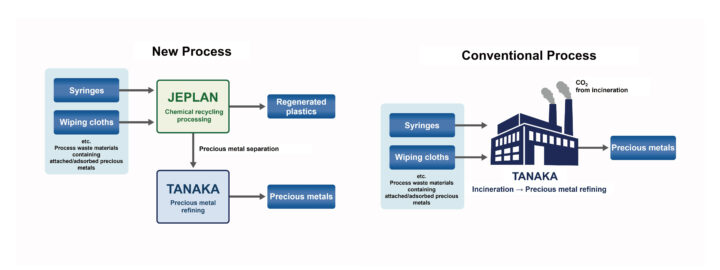

Since its founding in 1885, TANAKA has been a leader in the precious metals industry, actively engaged in recycling these limited and valuable resources. Among the process waste materials received from customers who request recycling, those containing organic materials (plastics) as main components with precious metals attached or adsorbed have traditionally been processed through incineration to remove the organic materials, with precious metals then recovered from the ash left behind.

■ Transforming the Precious Metal Recovery Process Through our Business Partnership

Through this business partnership, we will work to address the issue of CO₂ emissions associated with incineration by considering the use of chemical recycling in addition to the conventional precious metal recovery process through incineration. The materials targeted for chemical processing include plastics such as syringes and wiping cloths. CO₂ emissions from the targeted precious metal recovery process are expected to be reduced to approximately 10% of conventional levels.

In addition, this process enables not only precious metal recovery, but also plastic regeneration, with TANAKA and JEPLAN each contributing to the realization of a decarbonized, circular society through their respective areas of expertise.

Images

■ About TANAKA(https://tanaka-preciousmetals.com/en/)

Since its foundation in 1885, TANAKA has built a portfolio of products to support a diversified range of business uses focused on precious metals. TANAKA is a leader in Japan regarding the volume of precious metals it handles. Over many years, TANAKA has manufactured and sold precious metal products for industry and provided precious metals in such forms as jewelry and assets. As precious metals specialists, all Group companies in Japan and worldwide collaborate on manufacturing, sales, and technology development to offer a full range of products and services. With 5,591 employees, the group’s consolidated net sales for the fiscal year ending December 2024, was 846.9 billion yen.

【Press Release (PDF)】